hardness test of metallic materials pdf|hardness of metals chart : services Metallic materials — Rockwell hardness test — Part 1: Test method 1 Scope This document specifies the method for Rockwell regular and Rockwell superficial hardness tests for scales A, .

webRoblox is the ultimate virtual universe that lets you create, share experiences with friends, and be anything you can imagine. Join millions of people and discover an infinite variety of immersive experiences created by a global community! Roblox is ushering in the next generation of entertainment. Imagine, create, and play together with .

{plog:ftitle_list}

Resultado da Mari Ávila (@eumariiavila) no TikTok |114.4K curtidas.27.4K seguidores.Vim Pra Fazer Sua Diversão ️🔥🔞.Assista ao último vídeo de Mari Ávila (@eumariiavila).

1.1 These test methods cover the determination of the Rockwell hardness and the Rockwell superficial hardness of metallic materials by the Rockwell indentation hardness prin-ciple. . PDF | This experiment was carried out in our university lab to determine hardness of metallic materials using Rockwell Hardness test | Find, read and cite all the research you . 4.1 The Rockwell hardness test is an empirical indentation hardnesstestthatcanprovideusefulinformationaboutmetallic materials. This information .Metallic materials — Rockwell hardness test — Part 1: Test method 1 Scope This part of ISO 6508 specifies the method for Rockwell regular and Rockwell superficial hardness tests .

Scope* 1.1 These test methods cover the determination of the Rockwell hardness and the Rockwell superficial hardness of metallic materials, including test methods for the .

Metallic materials — Rockwell hardness test — Part 1: Test method 1 Scope This document specifies the method for Rockwell regular and Rockwell superficial hardness tests for scales A, .Metallic materials — Rockwell hardness test — Part 2: Verification and calibration of testing machines and indenters 1 Scope This part of ISO 6508 specifies two separate methods of . The purpose of this Guide is to explain the causes of variability in Rockwell hardness test results and to supplenment the information given in test method standards with .

ISO 6508-1:2015 specifies the method for Rockwell regular and Rockwell superficial hardness tests (scales and applicable range of application according to Table 1) for metallic materials .

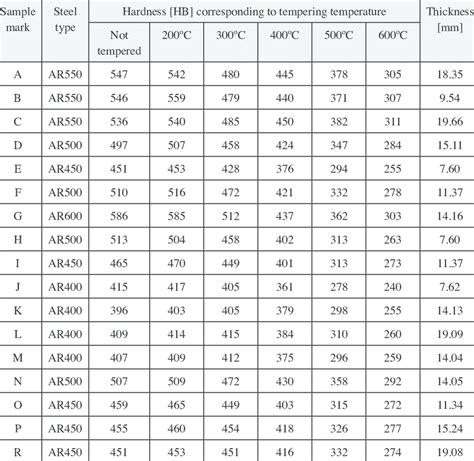

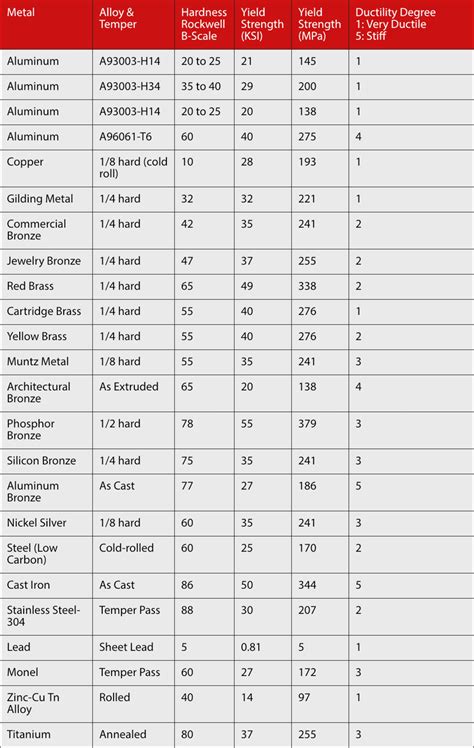

Metallic materials — Rockwell hardness test — Part 1: Test method. Edition 4 2016-08. Withdrawn. ISO 6508-1:2016. 70460. ISO 6508-1:2016 Metallic materials — Rockwell hardness test Part 1: Test method. Withdrawn (Edition 4, 2016) . PDF | Mechanical Properties of Materials | Find, read and cite all the research you need on ResearchGate . that tensile strength is proportional to the hardness of the metal following the . 4.1 The Brinell hardness test is an indentation hardness test that can provide useful information about metallic materials. This information may correlate to tensile strength, wear resistance, ductility, or other physical characteristics of metallic materials, and may be useful in quality control and selection of materials.At lower test loads the Vickers hardness may be load-dependent. In Table 2 are given the Vickers hardness numbers for a test load of 1 kgf. For obtaining hardness numbers when other test loads are used, the Vickers hardness number obtained from Table 2 is multiplied by the test load in kilograms-force (Table 3). 1.

3.4 Vickers hardness test—an indentation hardness test using calibrated machines to force a square-based pyramidal diamond indenter having specified face angles, under a prede-termined force, into the surface of the material under test and to measure the diagonals of the resulting impression after removal of the force.This part of ISO 6507 specifies the Vickers hardness test method, for the three different ranges of test force for metallic materials (see Table 1). Table 1 — Ranges of test force Ranges of test force, F N Hardness symbol Designation F W 49,03 W HV 5 Vickers hardness test 1,961 u F < 49,03 HV 0,2 to < HV 5 Low-force Vickers hardness test 4.1 The Brinell hardness test is an indentation hardness test that can provide useful information about metallic materials. This information may correlate to tensile strength, wear resistance, ductility, or other physical characteristics of metallic materials, and may be useful in quality control and selection of materials.4.1 The Brinell hardness test is an empirical indentation hardness test. Brinell hardness tests provide useful information about metallic materials. This information may correlate to tensile strength, wear resistance, ductility, or other physical characteristics of metallic materials, and may be useful in quality control and selection of materials.

This part of ISO 6507 specifies the Vickers hardness test method, for the three different ranges of test force for metallic materials (see Table 1). Table 1 — Ranges of test force Ranges of test force, F N Hardness symbol Designation F W 49,03 W HV 5 Vickers hardness test 1,961 u F Low-force Vickers hardness test < 49,03 HV 0,2 to < HV 5

steel hardness testing methods

sheet metal hardness chart

A Reference number ISO 6508-1:1999(E) INTERNATIONAL STANDARD ISO 6508-1 First edition 1999-09-01 Metallic materials — Rockwell hardness test — Part 1: Test method .

4.1 The Rockwell hardness test is an empirical indentation hardness test that can provide useful information about metallic materials. This information may correlate to tensile strength, wear resistance, ductility, and other physical characteristics of metallic materials, and may be useful in quality control and selection of materials.

ISO 376, Metallic materials — Calibration of force-proving instruments used for the verification of uniaxial testing machines ISO 6507-1, Metallic materials — Vickers hardness test — Part 1: Test method ISO 6508-1, Metallic materials — Rockwell hardness test — Part 1: Test method

This document specifies the Vickers hardness test method for the three different ranges of test force for metallic materials, including hard metals and other cemented carbides (see Table 1), metallic coatings and other inorganic coatings.. The Vickers hardness test is specified in this document for lengths of indentation diagonals between 0,020 mm and 1,400 mm.

4.1 The Brinell hardness test is an indentation hardness test that can provide useful information about metallic materials. This information may correlate to tensile strength, wear resistance, ductility, or other physical characteristics of metal-lic materials, and may be useful in quality control and selection of materials.SC 3, Hardness testing. This second edition cancels and replaces the first edition (ISO 6506-4:2005), which has been technically revised. ISO 6506 consists of the following parts, under the general title Metallic materials — Brinell hardness test: — Part 1: Test method — Part 2: Verification and calibration of testing machinesISO 6506-4, Metallic materials — Brinell hardness test — Part 4: Table of hardness values Only informative sections of standards are publicly available. To view the full content, you will need to purchase the standard by clicking on the "Buy" button.well hardness test except that smaller preliminary and total test forces are used. 3.1.5 verification—checking or testing to assure conform-ance with the specification. 4. Significance and Use 4.1 The Rockwell hardness test is an empirical indentation hardness test. Rockwell hardness tests provide useful informa-tion about metallic materials.

Metallic materials — Vickers hardness test — Part 2: Verification and calibration of testing machines 1 Scope This document specifies a method of verification and calibration of testing machines and diagonal measuring system for determining Vickers hardness in .Metallic materials - Rockwell hardness test - Part 1: Test method (ISO 6508-1:2023) Matériaux métalliques - Essai de dureté Rockwell - Partie 1: Méthode d'essai (ISO 6508-1:2023) Metallische Werkstoffe - Härteprüfung nach Rockwell - Teil 1: Prüfverfahren (ISO 6508-1:2023) This European Standard was approved by CEN on 13 November 2023.

METHOD FOR BRINELL HARDNESS TEST FOR METALLIC MATERIALS ( Third Revision) 1 Scope This part of ISO 6506 specifies the method for the Brinell hardness test for metallic materials and is applicable up to the limit of 650 HBW. For specific materials and/or products, particular International Standards exist (i.e. ISO 4498-l). 2 Normative referencesISO 6506-1:2014 specifies the method for the Brinell hardness test for metallic materials. It is applicable to both fixed location and portable hardness testing machines. For some specific materials and/or products, particular International Standards exist (e.g. ISO 4498) and make reference to this International Standard.ISO 6508-2:2015, Metallic materials — Rockwell hardness test — Part 2: Verification and calibration of testing machines and indenters; ISO 6508-3:2015, Metallic materials — Rockwell hardness test — Part 3: Calibration of reference blocks; Only informative sections of standards are publicly available. To view the full content, you will .

well as tension, hardness, torsion, and impact tests in particular. Mechanical Testing Mechanical tests (as opposed to physical, electrical, or other types of tests) often involves the deformation or breakage of samples of material (called test specimens or test pieces). Some common forms of test specimens and loading situations are shown in .%PDF-1.4 %ÓôÌá 1 0 obj /Type/Catalog /Pages 2 0 R /Metadata 136 0 R /Outlines 331 0 R /PageMode/mlfjlu >> endobj 2 0 obj /Type/Pages /Count 12 /Kids[20 0 R 31 0 R 41 0 R 43 0 R 45 0 R 47 0 R 66 0 R 73 0 R 114 0 R 116 0 R 118 0 R 135 0 R] .SC 3, Hardness testing. This second edition, together with ISO 6506-4, cancels and replaces the first edition (ISO 6506-1:1999), which has been technically revised. ISO 6506 consists of the following parts, under the general title Metallic materials — Brinell hardness test: ⎯ .

1.1 These test methods cover the determination of the Rockwell hardness and the Rockwell superficial hardness of metallic materials by the Rockwell indentation hardness principle. This standard provides the requirements for Rockwell hardness machines and the procedures for performing Rockwell hardness tests. The common ASTM and ISO standards for the four most popular hardness tests in metallic materials are listed below: ASTM E10: This standard covers Brinell hardness testing in . This standard contains the details for the Vickers hardness test in metallic materials. ISO 6508: This standard is very similar to ASTM E18, as it deals with the .

rockwell hardness chart for metals

metals ranked by hardness

Resultado da 1 dia atrás · Notícias. Mais de 25 mil mulheres e menores foram mortos por Israel em Gaza, diz Pentágono. O secretário de Defesa dos Estados .

hardness test of metallic materials pdf|hardness of metals chart